At present, zirconia ceramics are used in various industries, such as shaft seal bearings, cutting components, molds, automobile parts, and even human body. In the field of consumer electronics, zirconia ceramics are favored by fingerprint identification module patches and mobile phone backplanes because its hardness is close to sapphire, but the total cost is less than 1 / 4 of sapphire, its bending resistance is higher than glass and sapphire, non-conductive and will not shield signals. Next, Kezhong ceramics will tell you about the application of precision ceramic parts in the following three areas:

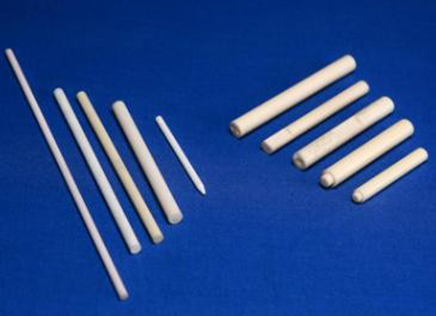

Zirconia ceramic parts

First, the field of consumer electronics accessories

The main application field is the back cover, which is mainly the upgrading and supplement of plastic, glass and metal materials. The second is the patch for fingerprint recognition or the shell of wearable devices, which mainly benefits from the improvement of the installation probability of fingerprint recognizer and the replacement of sapphire. It is used for small structural parts such as lock screen and volume key, which is a continuation of the key business of precision ceramic parts in the era of functional machine.

Second, the field of Superalloy filtration

Ceramic products made by ceramic parts sintering manufacturers are also widely used in the field of Superalloy filtration. Not only does zirconia ceramic parts play a good and stable effect in the filtration of molten steel continuous casting field, but also can effectively remove non-metallic impurities mixed with molten steel by foam ceramic products.

Third, the field of auto parts

Because zirconia ceramic parts have high strength and good toughness, it is also a significant advantage of this ceramic product. Therefore, with these two advantages, zirconia ceramic parts are widely used in the field of auto parts. Zirconia ceramic products can be used in relevant components of the engine, such as connecting rod and piston cap, which will greatly increase the market demand of ceramic parts.

The market will always choose high-quality and high-performance materials as the materials of precision parts to ensure the quality stability and safety performance of products. In recent years, the development of precision ceramic parts is precisely because of its unique performance. It is believed that in the next few years, precision ceramic parts will be favored by more fields and industries and make greater contributions to human industrial exhibition